LNG

GWC Italia offers a wide range of cryogenic service Ball Valves installed with LNG transmission, treatment, liquefaction and storage, whether onshore or on floating production & storage vessels.

Liquefied Natural Gas (LNG) comprises of between 85% & 90% methane gas, it undertakes several processes of treatment from condensate removal, gas treatment and liquefaction to transfer and storage. The liquified gas is easily transferred by specialist tankers to world markets or via pipelines.

Ball valves required to operate down to -161° C presents a series of challenges in the design, manufacturing and testing of these valves, in particular the seals become prone to hardening and at risk of failure in service.

GWC Italia has invested extensively in developing a wide range of cryogenic Floating & Trunnion Ball Valves with in-house cryogenic testing facilities to prove designs and ensure they meet detailed testing and validation requirements prior to shipment.

Floating Ball Valve - Cryogenic

Side-Entry (split-body) two or three pieces bolted construction, Seat-supported Ball, renewable seats, Full or Reduced Bore, Bi-Directional.

Read moreTrunnion Mounted Ball Valve Side Entry Bolted Body – Cryogenic

Side-Entry (split-body) two or three pieces bolted construction, Trunnion-supported, Floating seats spring energized, Full or Reduced Bore, Bi-Directional.

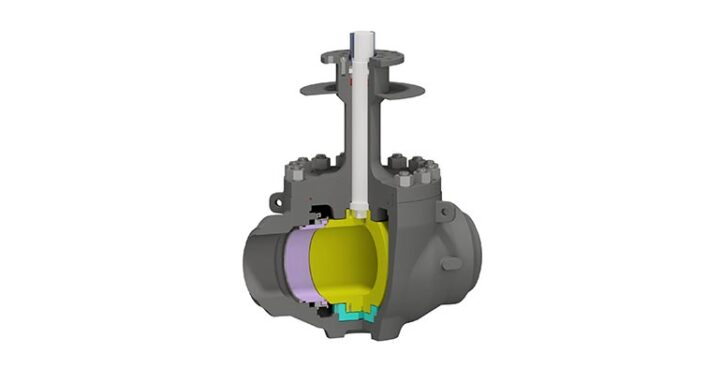

Read moreTrunnion Mounted Ball Valve Top Entry – Cryogenic

Top-Entry, Trunnion-supported, Floating seats spring energized, Full or Reduced Bore, Bi-Directional

Read more